Automotive Sheet Metal Fabrication in China

Are you looking for an automotive metal parts manufacturer in China? We work with international car makers and parts suppliers around the world. We specialize in custom automotive sheet metal parts for vehicles of all types, including passenger cars, trucks, and electric vehicles. Our team works closely with you to fabricate exact parts that match your design and quality needs. With our modern factory and experienced engineers, we turn your ideas into real metal parts you can rely on.

Our Automotive Capabilities – From Prototypes to Production

We offer complete automotive sheet metal fabrication in China, handling projects from single prototypes to

full production runs. This means we can help you at every stage of development – from initial prototype

fabrication for fit and function testing, to mass production of parts in the thousands. We can quickly make

prototype parts so you can test and improve your designs. When you are ready for volume production, we have

the production lines and tools to deliver consistent parts at scale. Whether you need just one test piece or

a large order of parts, we deliver with the same focus on quality.

We use modern machines and skilled workers to make sure every part is made correctly. Our engineers can also

help improve your design to make it easier to produce. For example, we might suggest a small change to a

bend or a different material to improve performance. By working with us from the start, you can go from

prototype to production without needing to find a new supplier. Fast turnaround on prototypes, along with

smooth production scaling, helps keep your automotive project on schedule.

Types of Parts We Manufacture

Our factory can make varies metal part found in a vehicle. Here are some examples of automotive metal components we manufacture:

-

01

Custom Parts and More

From small clips to complex welded assemblies, we can fabricate almost any custom automotive sheet metal part you need.

-

02

Housings and Enclosures

Sturdy metal boxes or covers for modules and electronics, including battery enclosures for EVs and other electrical boxes.

-

03

Body Panels and Frames

Structural panels and frame pieces (such as seat frames and interior panels) that give the vehicle body its shape and strength.

-

04

Heat Shields and Exhaust Components

Thin metal shields for exhaust systems and engine areas to protect against heat.

-

05

Brackets and Mounting Hardware

Metal brackets and supports that hold parts in place (for engines, suspensions, etc.).

Materials Used in Automotive Metal Parts

Not sure which material is suitable for your part? Our engineers will recommend the optimal choice based on

your part’s function, required strength, weight considerations, and budget. We can also source specialized

materials if your project requires them.

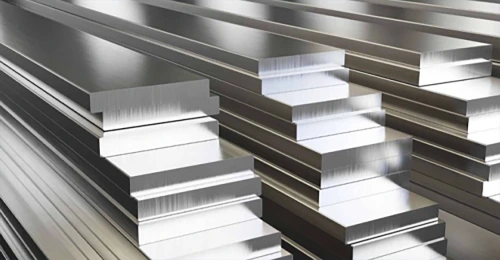

We work with a variety of quality metals to meet different automotive needs. Choosing the right material is

important for achieving the strength, weight, and cost targets of your project. Common materials we use

include:

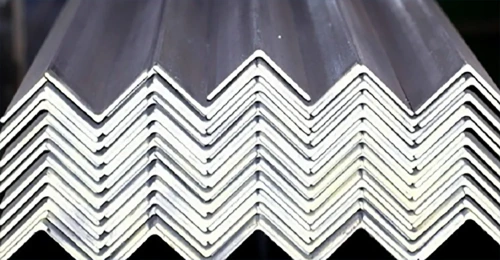

Steel (Mild and Galvanized)

Mild carbon steel is cost-effective and strong, used for many brackets and structural parts. We also offer galvanized steel (steel coated with zinc to resist rust) for parts that need extra corrosion resistance, such as body panels.

Stainless Steel

For components that demand high strength or need to withstand heat and weather (for example, exhaust parts or trim), stainless steel is a perfect choice. It’s known for its strength and durability, and it’s often used for structural parts that require high load-bearing capacity.

Aluminum Alloys

Aluminum is much lighter than steel yet still strong. Using aluminum helps reduce overall vehicle weight while maintaining structural integrity. We often use aluminum in parts like engine covers and electric vehicle sheet metal parts where saving weight is important for performance and range.

Other Metals

We can also fabricate with other metals such as copper or brass (often used in electrical components for their conductivity), depending on your needs. Our Materials page provides more details on the metals we handle and their properties.

Advanced Fabrication Processes

Whether you need laser cutting, precision CNC bending, high-volume stamping, expert welding, or a full finishing

solution, we have the ability to deliver. By handling all these steps under one roof, we ensure better quality

control and shorter production times for your automotive parts.

We use advanced sheet metal processes to cut, bend, join, and finish parts with a high degree of accuracy. These

capabilities allow us to meet the strict demands of automotive production.

Our manufacturing capabilities include:

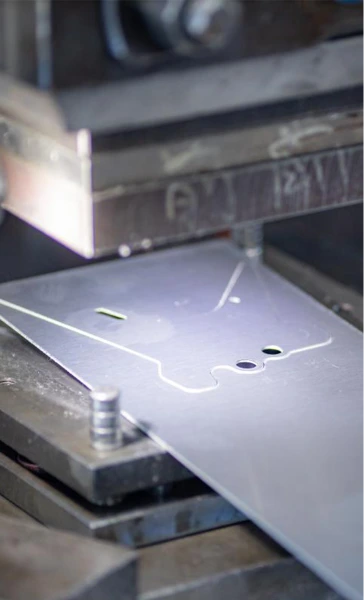

High-powered CNC laser cutting allows us to cut complex shapes with clean edges and tight tolerances. This process is ideal for prototypes and intricate parts, as it produces minimal waste and does not warp the metal.

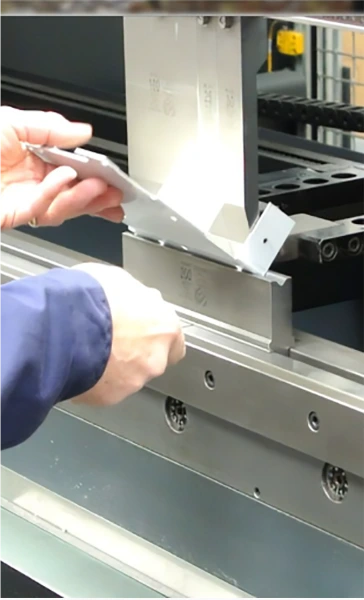

Using modern press brakes, we can bend and form metal sheets into precise angles and curved shapes. CNC-controlled bending ensures consistency across every part, so each one fits exactly as designed.

For high-volume production of simpler shapes (like brackets or panels), we offer stamping with custom dies. Metal stamping is very efficient for large quantities, delivering parts with consistent accuracy and durability. Each stamped piece comes out identical, which is great for maintaining quality in mass production.

We provide both manual and robotic welding (MIG, TIG, and spot welding) to join metal parts into assemblies. Our certified welders create strong, clean welds on steel, stainless, and aluminum parts. We can weld sub-components (like nuts or studs) to sheet metal pieces and assemble multi-piece units as needed, making sure everything fits together correctly.

To give your parts the required protection and appearance, we offer in-house finishing services. This includes deburring (smoothing sharp edges), sandblasting, powder coating, plating, and anodizing for corrosion resistance and appearance. See our Surface Finishing services for more on the coatings and paint finishes we can apply.

Quality is paramount in the automotive industry, where safety and reliability are extremely

important. We maintain strict quality assurance processes to deliver parts that meet international

automotive standards. We are ISO 9001 certified and follow the IATF 16949 automotive quality

management system. (IATF 16949 is a globally recognized standard for automotive manufacturing that

builds on ISO 9001.) In fact, it is a mandatory certification for suppliers working with major car

manufacturers. By following these strict standards, we make sure our processes are consistent and

our products are dependable.

Our quality control procedures include checks and tests at each stage of production. For example, we

inspect the first sample part to verify all dimensions are correct. During production, our team

takes regular measurements and uses gauges to maintain tight tolerances (accuracy) on important

features. We also provide material certifications and can do additional testing (like weld strength

tests or coating thickness checks) upon request, so you have full confidence in the parts you

receive.

Every automotive part we make goes through a final inspection before shipment. We double-check that

all hole positions, bends, welds, and finishes match your specifications and drawings. Our goal is

zero defects – and we approach that through careful planning, skilled work, and continuous

improvement. If required, we can also support PPAP documentation or other quality reports to help

with your part approval process.

By choosing us as your automotive sheet metal supplier, you gain a partner committed to quality and

compliance. We invest in employee training, keep our equipment calibrated, and stay up-to-date with

the latest industry standards. This dedication to quality ensures the parts you receive will fit and

function reliably in your vehicles.

We are proud to support a wide range of clients in the automotive sector. Our customer base includes

passenger car OEMs, commercial vehicle and truck manufacturers, new EV startups, and Tier 1

automotive suppliers. Whether you are building standard sedans, heavy-duty trucks, or the next

cutting-edge electric car, our fabrication services can be tailored to your needs.

Working with international clients means we are familiar with global standards and shipping

logistics. We have experience exporting automotive parts to different countries. We provide clear

communication and timely delivery of your parts. We can handle different regional requirements, from

metric drawings to various compliance documents, making it easy to do business across borders.

In addition to automotive, we also serve other high-tech industries that demand quality metal

fabrication. For example, we have dedicated pages about our work in the Aerospace and Industrial

sectors. The experience we have gained in these fields also improves our ability to serve automotive

clients. We understand the importance of reliability and precision in every industry we operate in.

Many of our automotive clients are repeat customers who consider us as a long-term manufacturing

partner. We believe in building strong relationships through honest service, consistent quality, and

helpful support. When you work with us, you’re not just buying a part – you’re gaining a China-based

manufacturing partner who is committed to your success.

Electric vehicles (EVs) bring new demands for lightweight and efficient components, and we are fully

equipped to support EV metal parts fabrication in China. We understand the importance of reducing

weight to improve electric driving range and managing heat in high-power electrical systems. Our

team has experience producing custom EV sheet metal parts that meet these challenges.

For example, we manufacture battery enclosures and trays for electric vehicle battery packs. These

enclosures are often made from aluminum to save weight while still providing strength and crash

protection. We ensure battery housings are built to precise dimensions so that battery modules fit

securely, and we can incorporate features like mounting brackets or cooling channels into the sheet

metal design.

We also produce electric motor mounts, inverter housings, and brackets for high-voltage components.

These parts need to be very accurate and strong to support heavy electric motors and sensitive

electronics. Our fabrication processes achieve the needed precision to make sure everything fits

together correctly, and we use robust materials that can handle the stresses and vibrations of EV

operation.

Heat management is another critical aspect for EVs. We fabricate heat shields and cooling plates

that help protect sensitive components (like batteries or power controllers) from heat. Using

thermally conductive metals and smart designs, we assist in dissipating heat away from hot spots or

shielding parts from external heat sources.

In summary, we stay at the forefront of EV manufacturing needs. We use lightweight materials and

innovative designs to help EV startups and established automakers build safer, lighter, and more

efficient electric vehicles. If you are developing an electric car or component, we can fabricate

the custom metal parts you need to make it a reality.

How to Work With Us – From RFQ to Delivery

Throughout this process, communication is key. Our team is responsive to emails and calls, so you will

always know the status of your project. We also stand behind our work – if you encounter any issue, we will

fix it promptly and make sure you are satisfied with the solution.

Working with us for your automotive sheet metal needs is straightforward. We support you through each step –

from the first inquiry to final production and beyond. Here is how a typical project works:

Request a Quote:

1. Contact us with your part drawings, 3D models, or even a rough sketch of what you need. Our engineering team will review the requirements and provide a detailed quote response. We’ll clarify any details with you (such as materials or dimensions) and then give you clear pricing along with an estimated lead time for production.

Prototype Development

2. For new designs or critical parts, we often begin with a prototype or small trial batch. Our rapid fabrication capabilities allow us to produce prototypes quickly – using methods like laser cutting and manual fabrication to avoid long tooling delays. You will receive the prototype parts for evaluation and test-fitting. We welcome your feedback at this stage. If any adjustments are needed, we work with you to refine the design or process.

Tooling & Production

3. Once you approve the prototypes and are ready to proceed, we move into production. For high volumes, this may involve creating custom molds or welding fixtures to speed up assembly. After tooling is set up, we begin full-scale manufacturing – whether it’s stamping out hundreds of brackets or bending and welding together complex assemblies. Throughout production, our project manager will keep you updated on progress.

Quality Assurance & Shipping

4. Before parts leave our factory, we perform final inspections as described above. We carefully package the parts to prevent any damage during shipping. We then arrange delivery to your location – whether by air for fast delivery or by ocean freight for cost efficiency – making the shipping process easy for you. We handle all export paperwork and customs clearance if needed. The parts will arrive ready to go straight into your production line.

Ready to Get Started?

As your automotive sheet metal fabrication partner, you get manufacturing expertise, dependable quality, and a team that truly cares about your project’s success. Contact us today to discuss your automotive metal part needs, or request a quote for your project. We are excited to work with you and provide the custom metal parts that will drive your automotive innovation forward.