Why Sheet Metal is Essential for Consumer Electronics

Sheet metal is a preferred material in consumer electronics because it provides strength, precise fit, and effective shielding from electromagnetic interference (EMI). It helps your electronic devices withstand everyday use while maintaining performance and appearance. Key benefits of using sheet metal for electronics include:

Precision & Accuracy

CNC machines precisely cut and shape metal, ensuring perfect alignment of electronic parts and consistent performance.

Durability

Sheet metal parts endure daily wear and resist deformation and damage, making your electronic products last longer.

Effective Shielding

Metal enclosures shield sensitive electronics from electromagnetic interference, improving performance and reliability.

Consumer Electronics Components We Manufacture

Whether your project involves small handheld devices or larger home electronics, we have the experience and

capabilities to fabricate precise metal parts suited to your needs.

We provide custom sheet metal fabrication services for many types of electronic devices. Common components

we manufacture include:

-

01

Metal Enclosures and Cases

Customized housing for computers, audio equipment, gaming consoles, and other electronics. These protect sensitive internal components while maintaining sleek aesthetics.

-

02

Panels and Covers

Attractive front and back panels for consumer electronics like media players, amplifiers, and communication devices, with precision-cut holes for controls and displays.

-

03

Brackets and Mounting Hardware

Precision metal brackets, supports, and mounting solutions tailored for securely fixing electronic components within devices.

-

04

Chassis and Frames

Structural frames for electronic assemblies, providing strength, stability, and alignment for internal parts.

-

05

Heat Sinks and Cooling Components

Custom fabricated heat sinks and metal cooling solutions for electronics that manage heat efficiently to maintain device performance

Consumer Electronics Sheet Metal Fabrication in China

We specialize in fabricating custom sheet metal parts for the consumer electronics industry. As a China-based manufacturer serving varies brands, we produce precise and durable metal components tailored specifically to your electronics manufacturing needs. From simple brackets to complex device enclosures, our team provides reliable sheet metal fabrication services to help you build quality electronic products.

Fabrication Processes Tailored for Consumer Electronics

Our complete in-house fabrication processes ensure that every part meets your design specifications and quality

requirements.

We use advanced sheet metal fabrication techniques to meet the precision demands of consumer electronics

manufacturing:

Laser cutting:

Our CNC laser cutting technology creates accurate, intricate shapes and cutouts in metal sheets. This ensures tight tolerances for fitting internal electronic.

CNC Bending

Precision bending forms metal sheets into exact shapes and angles, essential for creating electronic enclosures and internal brackets.

Metal Stamping

For high-volume production, stamping efficiently produces consistent components such as metal brackets and small parts.

Welding & Assembly

Skilled welding (TIG, MIG, and spot welding) is used to assemble metal parts securely, creating stable and durable electronic chassis and enclosures.

Surface Finishing

We apply finishing techniques like powder coating, anodizing, polishing, and plating, enhancing both appearance and corrosion resistance.

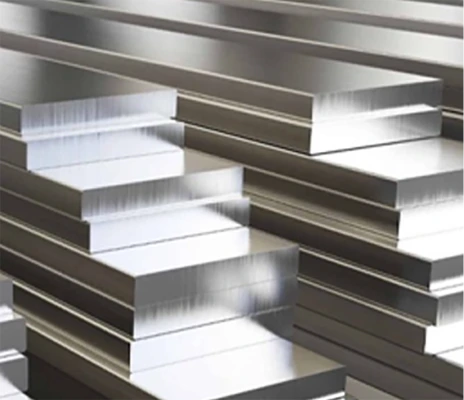

Materials Suited for Consumer Electronics

We help you choose the optimal material to meet your product’s performance requirements, aesthetic goals, and

cost targets.

Selecting the right materials significantly impacts your product’s quality and performance. Commonly used metals

in consumer electronics include:

Lightweight, durable, and good for thermal management. Aluminum is ideal for laptops, mobile devices, and portable electronics.

Offers strength and an attractive finish. It’s often used for premium electronics housings and frames, providing lasting durability and corrosion resistance.

Provides good durability and cost-effectiveness. It’s suitable for internal brackets and frames in large-scale production.

Used primarily for connectors and internal electronic components due to great electrical conductivity.

Quality and Compliance

Quality is critical in appliance manufacturing. We hold ISO 9001:2015 certification, reflecting a robust quality

management system. This means we have strict controls for each step – from material inspection to final audits –

so you receive consistent, quality parts. For example, ISO 9001 requires effective quality control measures and

continuous improvement. In practice, that means accurate dimensional inspections, traceability of materials, and

detailed documentation on every job. Our dedication to quality helps ensure your appliance components perform

safely and reliably.

Our robust quality control system helps you deliver quality electronic products to consumers.

Our quality processes include:

Regular Inspections: Complete compliance with industry-specific standards and certifications essential for consumer electronics markets.

Material Traceability: Detailed tracking and documentation of materials and production batches, ensuring quality accountability and traceability.

Compliance Documentation: Complete compliance with industry-specific standards and certifications essential for consumer electronics markets.

How We Work With You

Working with us means having a dedicated manufacturing partner supporting you at every step of your electronics production cycle.Throughout this process, our engineers and project managers maintain clear and responsive communication, keeping you informed at each stage.

Request for Quote (RFQ)

1.You send us your drawings or specifications. We promptly provide competitive pricing and manufacturing lead times.

Prototype Development

2.Quick prototyping allows you to evaluate and refine your designs efficiently, minimizing time to market.

Production

3.From small-batch custom orders to large-scale OEM production runs, we handle projects efficiently with consistent quality.

Packaging & Delivery

We ensure secure packaging tailored to international shipping standards, delivering your components safely to your location.

Ready to Start Your Electronics Project?

If you’re looking for a partner in China for your next consumer electronics project, we are here to deliver precision sheet metal fabrication tailored to your needs. Whether you’re developing a new product or improving an existing one, contact us today to discuss your requirements or request a detailed quote.