Medical Sheet Metal Fabrication in China

We are a precision sheet metal fabrication company in China serving medical device and healthcare equipment makers. We know you need parts that meet strict medical standards. Our factory is ISO 13485:2016 certified, so our quality management system is built for medical-grade production. We support your projects from design through delivery, helping you get custom sheet metal parts for medical equipment based on your requirements.

Why Sheet Metal Is Used in Medical Equipment

These strengths make sheet metal ideal for

housings, frames, and components in surgical tables, imaging systems, diagnostic machines, and lab

equipment.

Sheet metal is widely used in medical devices because it is strong, reliable, and easy to keep clean. It

lets you make parts that last under tough conditions. For example, sheet metal (especially stainless steel)

resists corrosion from cleaning chemicals and high heat, so it stays intact through repeated sterilization.

It also can be cut and formed with tight accuracy, so complex devices fit and work exactly as designed. In

practice, this means:

Durable and corrosion-resistant

Sheet metal parts (like stainless steel 316) withstand heavy use and sterilization without rusting or warping.

Easy to clean

Metals have smooth, non-porous surfaces that can be sanitized quickly and thoroughly.

Precision

CNC laser cutting and bending can hold very tight tolerances, so parts fit perfectly in medical machines.

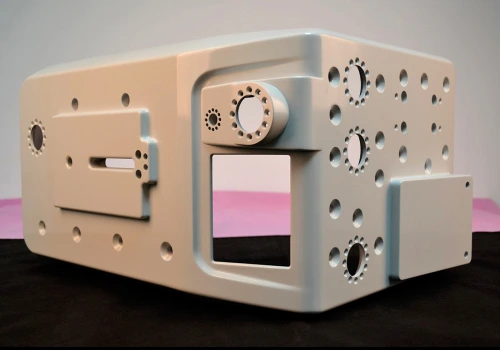

Medical Parts and Products We Manufacture

We produce a wide range of sheet metal parts used in healthcare and medical devices. You can choose us to handle small details or large assemblies. Common parts and products include:

Custom panels and cases for imaging machines, diagnostic equipment, control cabinets, etc.

Mobile supply carts, IV poles, instrument cabinets, and wheeled stands made from stainless steel or aluminum.

Precision mounting brackets, tubular frames, chassis, and racks for monitors, pumps, or instrumentation.

Surgical and laboratory trays, test-tube racks, and shelving built to exact dimensions for clean use.

Any specific device component – from covers and panels to large metal frames – we can fabricate per your drawings.

For example, one fabricator reports building high-tech imaging machine housings and surgical instrument trays for medical customers. We’ll work with your design ideas or prints and turn them into real parts. Because every medical project is unique, we’re flexible to make one-offs or long runs. If you need a custom sheet metal part for your medical equipment, just let us know the specs and we’ll handle it.

Processes We Use

We have the full range of advanced fabrication processes to make your parts. To achieve precise and repeatable results, we combine automated machines with skilled welding and finishing. Our key processes include:

Laser cutting:

Precision CNC lasers cut metal sheets to shape. Our laser machines can cut complex patterns in stainless steel, aluminum, or coated steel with minimal heat distortion.

Press brake bending:

We use CNC bending equipment to form flanges, angles, and curves. This lets us shape heavy sheet metal accurately and consistently.

Welding and assembly:

TIG and MIG welding are used for joining parts and making assemblies. We weld frames, brackets, and enclosures with quality that meets medical standards. After fabrication, our team can assemble components or sub-assemblies as needed.

Stamping:

We offer stamping with custom dies. Metal stamping is very efficient for large quantities, delivering parts with consistent accuracy and durability. Each stamped piece comes out identical, which is great for maintaining quality in mass production.

Surface finishing:

To ensure durability and sterilizability, we offer finishing like powder coating, plating, anodizing, or passivation. For example, we provide anodizing for aluminum parts and electropolishing or powder coating to enhance corrosion resistance.

In short, we follow a full fabrication workflow (laser cutting → forming/bending → welding → finishing → assembly). For detailed capabilities, see our Fabrication page and Bending capabilities. We also have a Surface Finishing page with examples of our finishes.

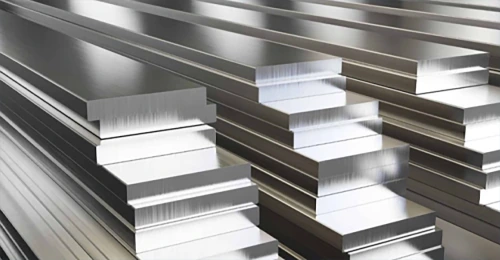

Materials Used

If you have a special alloy or a coated metal in mind, let us know. We’ll recommend the suitable material

for your application. (Learn more on our Materials page.)

We work with medical-grade metals commonly used in healthcare, including:

Stainless Steel (304, 316, etc.)

Widely used in medical parts for its high strength and corrosion resistance. For example, stainless steel 316 resists rust and tolerates the high heat and chemicals of sterilization without distortion. Its smooth polished surface is ideal for sterile environments.

Aluminum (5052, 6061, etc.)

A lightweight option that is easy to form and weld. Aluminum 5052 is corrosion-resistant and very workable. It’s good for equipment where weight matters, like mobile carts or instrument mounts.

Coated Steel

For some parts we offer powder-coated or painted carbon steel. These coatings add extra corrosion protection and allow color coding of parts. Powder coating also creates a durable, easy-to-clean finish.

ISO 13485:2016 Compliance

Traceability and records:

We trace materials and parts through production. Each batch has documented records, and our inspections and tests are logged for full traceability.

Regulatory compliance:

Our processes are audited to meet medical industry regulations. ISO 13485 requires us to demonstrate compliance with applicable medical device directives.

Continuous improvement:

We track nonconformances and corrective actions. This leads to better product reliability and process improvements.

As an ISO 13485:2016 certified sheet metal fabricator, we follow a quality management system

specifically for medical devices. This standard covers every stage of manufacturing and ensures patient

safety. It means we have documented procedures for design controls, supplier management, testing, and

change control. Some important points of our ISO 13485 system include:

In practice, you can follow our documentation. We provide certificates of conformity and quality

inspection reports for every order. Working under ISO 13485 means your parts will have the safety and

quality assurance needed for medical markets. The certificates are held at our facilities and can be

verified upon request.

Sheet Metal Applications In Medical Devices

In short, if you make medical or lab equipment – from small handheld devices to large diagnostic systems

– our sheet metal services can supply parts like enclosures, panels, trays, and frames that fit your

needs.

Our sheet metal parts serve many areas of healthcare manufacturing. Common applications include:

Diagnostics equipment:

Parts for imaging machines (MRI, CT, ultrasound), analyzers, and laboratory instruments. (Many OEMs use welded frames and enclosures in these machines.)

Surgical and procedure devices:

Housings and trays for surgical instruments, carts for operating rooms, and frames for patient monitors. (Fabricated trays and instrument holders are used in operating theaters and clinics.)

Imaging systems:

Custom metal housings and racks in X-ray, MRI, and ultrasound machines, where precision and shielding are required. For example, MRI and CT scanner panels often use welded sheet metal frames.

Hospital furniture and support:

Durable beds, cabinets, and carts. (Sheet metal is ideal for hospital beds and storage cabinets because it’s strong and easy to clean.)

Laboratory equipment:

Racks, cabinets, fume hood frames, and test equipment frames in labs. Our parts help build reliable lab machines and storage units.

How We Work With You

We pride ourselves on clear communication. You deal directly with our engineers

and project managers (not a faceless factory). We explain any technical issues and welcome your feedback.

This collaborative approach – combined with our certified quality system – helps ensure your parts arrive

and work as intended.

We work closely with customers to ensure a smooth process from quote to delivery. Here’s how it typically

goes:

Request for Quote (RFQ)

1.You send us drawings, CAD files, or specifications. We provide a fast, competitive quote. (We often offer DFM feedback to improve manufacturability.)

Prototyping

2.After agreeing on design and price, we build prototypes or pre-production samples. You review and test these parts for fit and function. Adjustments are made if needed.

Production

3.Once the design is finalized, we schedule production. Our ISO 13485 QMS covers the entire run – from material ordering to final inspection. In-process inspections ensure parts match the agreed tolerances and specifications.

Documentation

4.For each shipment, we include inspection reports, material certificates, and any required compliance documents. Because we follow ISO 13485, our documentation meets medical device regulations (inspection reports, traceability logs, etc.).

Shipping and Support

5.We handle careful packaging and can arrange shipping. Throughout, our team stays in touch to answer questions and keep you updated.

Ready to get started?

Contact our sales team today to discuss your project. You can request a quote or simply contact us for more information. We look forward to working with you on your next medical equipment project.