Why Sheet Metal Matters in Robotics

Sheet metal is critical in robotics because it provides strength, precision, and versatility. Robots require parts that can handle continuous movement, vibrations, and precise alignments. Sheet metal delivers the required durability and dimensional accuracy.

Precision

Robots rely heavily on accuracy. Sheet metal parts made with CNC technology ensure your robots work precisely every time.

Durability

Metal parts handle repetitive tasks without wearing out quickly, making them perfect for robotics.

Customizable Designs

Sheet metal is easily formed into complex shapes, making it ideal for unique robot components and structures.

Robotics Components We Manufacture

Whatever your robotics application demands, our custom fabrication services ensure every component meets your

exact specifications.

We manufacture a variety of custom robotics metal parts, including:

Chassis and Frames

Precision-cut and formed metal structures for robot bodies and bases.

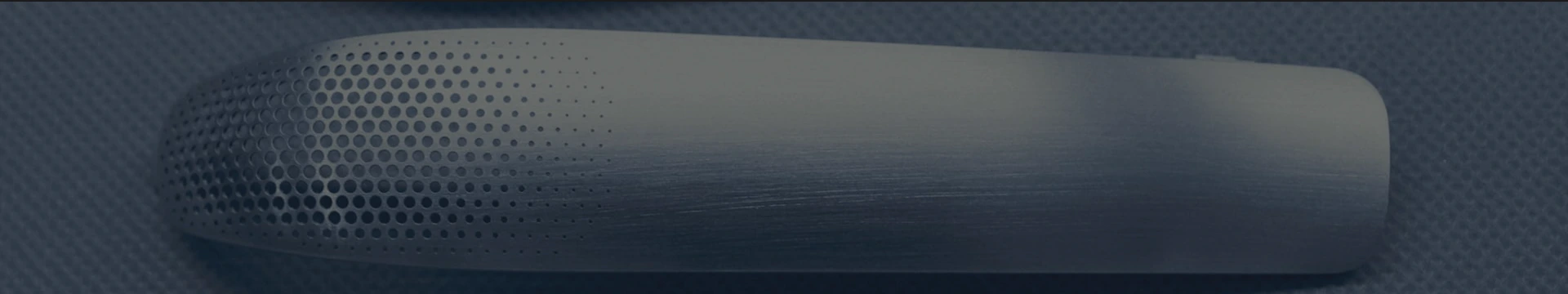

Enclosures and Covers

Protective casings and housing for electronic and mechanical components, ensuring durability and safety.must be strong and precise.

Mounting Brackets and Fixtures

Custom brackets for attaching sensors, motors, and controllers securely.

Sensor Mounts

Customized mounts for sensors, ensuring correct positioning for accurate readings.

Manipulator Arms and Joints

Structural metal parts for robotic arms, offering accurate movement and load-bearing capabilities.

Base Plates and Platforms

Stable metal platforms and base plates providing structural support and alignment.

Robotics Sheet Metal Fabrication in China

We offer precision sheet metal fabrication services specifically designed for robotics manufacturers. From industrial robots to automated machines, we provide the custom metal parts you need to build reliable, efficient robotic systems. As your China-based partner, we help you meet the demands of modern robotics applications by providing accurate, durable sheet metal components.

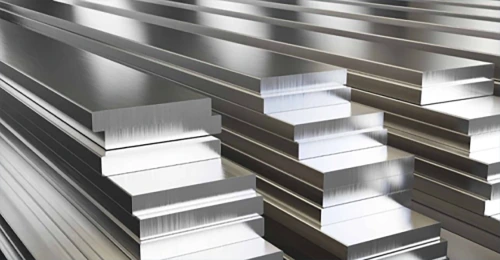

Materials Optimized for Robotics

We work closely with you to choose the suitable material for your specific robotics application. Material selection significantly impacts the performance and longevity of robotic systems. We commonly fabricate robotics parts using:

Aluminum

Lightweight yet robust, aluminum helps reduce robot weight while maintaining strength and durability.

Carbon Steel

Used for high-strength components, particularly structural elements that support heavy loads or withstand continuous motion.

Stainless Steel

Ideal for parts requiring strength, corrosion resistance, and cleanliness. It’s commonly used in industrial robots and cleanroom robotics.

Specialty Alloys

Nickel alloys and titanium can also be used where extreme strength, heat resistance, or lightweighting is required.

Industries and Robotics Applications Served

No matter your robotics project, we deliver tailored sheet metal solutions that ensure reliability, safety, and

precise performance.

We support robotics applications across diverse industries, such as:

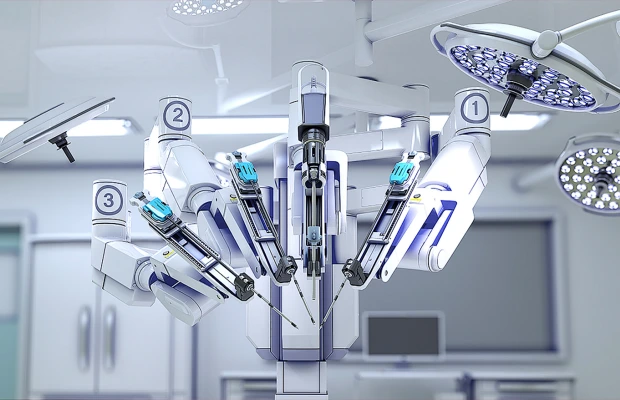

Medical Robotics

Medical Robotics

Precision sheet metal components for surgical robots, diagnostic machines, and automated laboratory equipment.

Agricultural Robotics

Agricultural Robotics

Components for autonomous vehicles and equipment used in farming, harvesting, and monitoring crops.

Automation Systems

Automation Systems

Parts for robotic automation used in warehouses, logistics, packaging, and distribution facilities.

Industrial Robotics

Industrial Robotics

Parts for robotic arms and automation systems used in factories and manufacturing lines.

Service Robotics

Service Robotics

Metal structures and enclosures for autonomous robots used in hospitality, retail, and logistics.

Quality Assurance & Compliance

Quality and consistency are at the core of robotics manufacturing. Our quality management system ensures every

part meets your specifications and requirements. We maintain certifications including ISO 9001:2015 and ISO

14001, ensuring our fabrication processes comply with international quality and environmental

standards.

Our commitment to quality helps ensure you get reliable, good performing robotics components as

you requested. All the certificates are held at our facilities and can be verified. We invite you visit our

facilities and have a coffee chat with our team.

Consistent Quality Checks

Each component undergoes rigorous inspection and measurement to meet dimensional accuracy.

Traceability

We keep detailed records of materials and processes, ensuring every part can be tracked and verified

Continuous Improvement

Regular audits and process improvements ensures our manufacturing standards remain high.

Working With Us: From Concept to Completion

Clear communication throughout the process ensures your project moves smoothly

from design to delivery.

Our streamlined approach makes collaborating with us straightforward:

Request for Quote (RFQ)

1.Submit your designs or specifications. We quickly review and provide detailed pricing and timelines.

Prototyping

2.We fabricate initial prototypes rapidly, allowing you to evaluate designs and make necessary adjustments.

Production

3.Once prototypes are approved, we efficiently scale production, ensuring consistency across every batch.

Quality Inspection

4. Each production batch undergoes thorough inspections, and reports are provided for full transparency.

Delivery and Support

5.Carefully packaged components are shipped to your location. We remain available after delivery to assist with any needs.

Request a Quote for Your Robotics Parts Today

Ready to get started on your robotics fabrication project? We are your partner in China for precision

sheet metal components. Contact us today to discuss your requirements or request a quote. Our expert

team is ready to provide guidance, support, and quality fabrication services tailored to your robotics

needs.

Let us help you bring your robotic systems to life with custom-made sheet metal parts designed precisely

for your applications.